Tube Laser Cutting Systems Lebanon

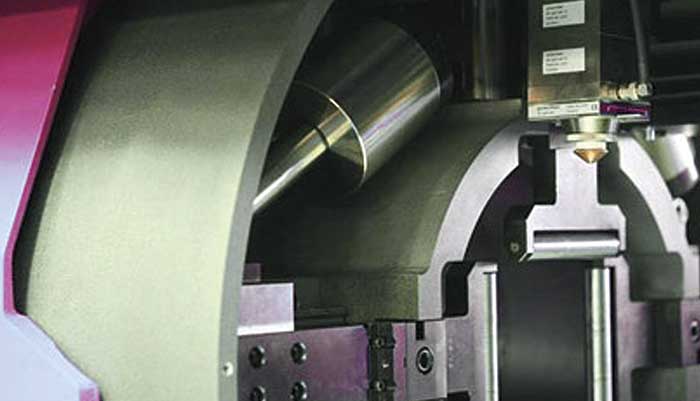

With laser generating technology, sheet laser cutting machines can now be sold with power outputs up to 12kW. A laser tube-cutting machine usually has a power consumption of 5 kW. Any more power would cause the tube to be cut on both sides simultaneously.

Let's take a look at the benefits of an automated tube and section bar storage with a Lasertube cutter system.